Crane manufacturers are increasing their focus on integrated service and quality

Over the past few years, many manufacturers have sought to extend the capabilities of their crane ERP software. Engineer-to-order and project-based manufacturing tools, along with planning and scheduling modules, have always been essential parts of any ERP software for the crane industry. But increasingly, crane manufacturers are recognizing the need to have an integrated quality system to help them address and comply with International Organization for Standardization (ISO) standards. Additionally, integrated service management is becoming a critical part of ERP for crane manufacturers. In this article, we’ll explain why these trends are emerging and how they impact the industry.

Integrated quality as part of ERP for the crane industry

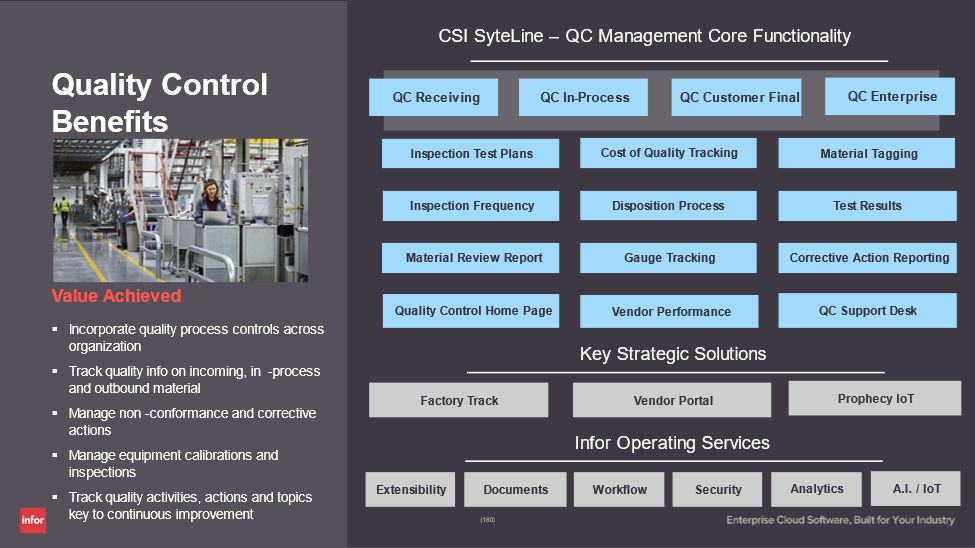

Quality control is especially important for crane manufacturers. Cranes need to be tested and inspected using many control points, ultimately capturing the data in a system of record. Crane manufacturers often need these records to prove compliance with ISO standards, including ISO13001, ISO1292, ISO3691, ISO13411, and ISO 1677. Having a native Quality Control System as part of the crane manufacturing ERP will help meet these quality control needs.

An integrated ERP quality control system can be used for inspecting parts, in-process inspections, and final acceptance testing. An integrated system can also be used to manage non-conformance and corrective actions. Documents can be tracked and viewed as part of the system.

The most simple and obvious benefit of having quality control as part of the ERP for crane manufacturers is that users will be on the same system, versus bouncing between loosely cobbled systems with light (or no) integration. This lack of integration increases mistakes and is inefficient because it often requires dual data entry.

It’s also difficult to pull accurate and comprehensive reports when using multiple systems, making quality audits arduous.

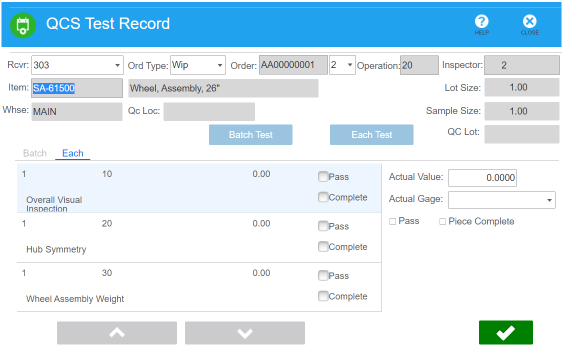

Additional capabilities in ERP for crane manufacturers include using an integrated shop floor mobile system for quality inspections. For example, Infor CloudSuite Industrial customers can use Infor Factory Track for multiple functions beyond quality, such as attendance, labor collection, material issues, material barcoding, and lot and serial trace.

Infor CloudSuite Industrial Factory Track allows for quality inspections on the shop floor using mobile devices.

Integrated service management and field service management

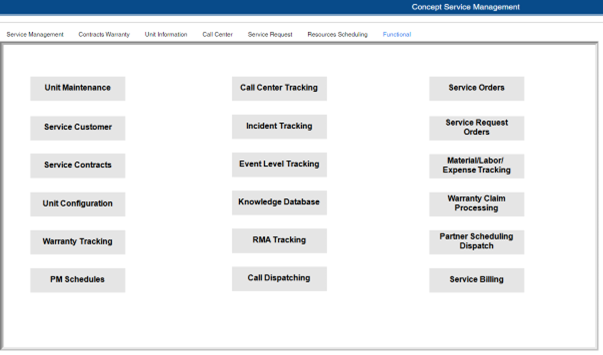

Another technology trend we are seeing with manufacturers is the search for crane ERP software that includes service management and the ability to track activities in the field, from installation to ongoing maintenance. The problems crane manufacturers have using third-party service systems are much like the issues that arise with an unintegrated quality system. Non-integration increases inefficiencies (such as dual data entry) and opportunities for mistakes. It also requires customer service agents to access two systems to find information relating to warranties, unit configuration, unit location, and repair and service history.

We often see crane manufacturers with no service system at all who have created workarounds, using work orders as service orders. However, the only way to capture field activities is on paper, which is not efficient and often not accurate.

Service - Installation and Delivery

A big part of an overall crane manufacturing project is managing the installation or delivery components. The project manager needs to ensure all transport and permitting is in place, and then collaborate with local contractors. It’s important for crane manufacturing ERP to support this element of the project.

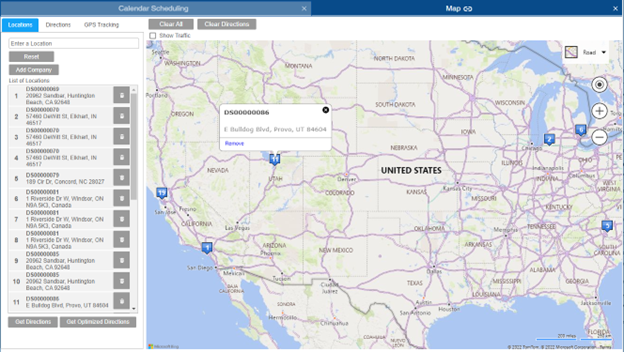

Some ERP applications have a service management module to address the related activities: schedule crews, get routing information, capture travel and expenses, and have GPS map visibility of crew locations.

A proper service management application in an ERP system can handle these requirements, from crane rental to truck scheduling. The prep, transport, and set-up costs also need to be captured as part of the project, so the manufacturer can measure and analyze true profitability.

Infor CloudSuite Industrial ERP provides crane manufacturers with a robust Service Management toolset to manage service activities, from installation to maintenance.

Service Management - Warranty and Service

Once the cranes are installed, many manufacturers have warranties and service contracts, or perform break/fix maintenance. The service management module within the crane ERP can assist with scheduling warranty work. The field service teams that perform corrective actions, repair work, and parts replacement on cranes can access complete unit configuration via their mobile devices. The as-built unit configuration is available to the service team because of the complete integration with the manufacturing module in the crane ERP software system. Not only can the field techs see the original configuration, but they can also see the history of repairs and current unit configuration where new parts have replaced existing parts. They can see serialized components, as well.

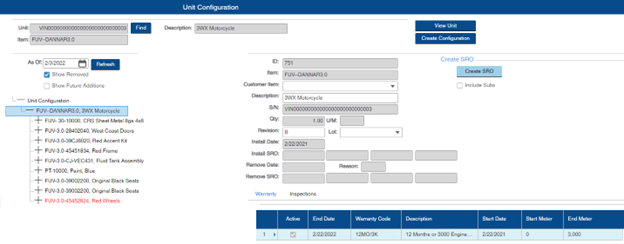

Infor CloudSuite Industrial ERP’s Service Management provides visibility into unit configuration and current configuration from previous repair and warranty work.

The service management application can facilitate field techs taking pictures, obtaining electronic sign off by the customer, and recording the labor and materials used on the service repair order. These costs can be attributed to the warranty or against a service contract, or be billed to the customer for repairs. The billing can happen instantaneously due to the accounting integration, which leads to increased cash flow and fewer days outstanding for the service department work.

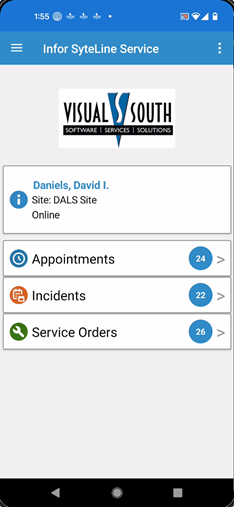

Infor CloudSuite Industrial ERP’s Service Management also includes full mobile capabilities for field techs doing installs, warranty work, service and maintenance contract work, or unscheduled repair jobs.

Related: ERP Requirements for Crane Manufacturers

Summary

The benefits of having an all-inclusive crane manufacturing ERP system are numerous. Yet there are limited options in the market that address the wide variety of functional needs for crane manufacturers, including quality control and service management. The team at Visual South can provide guidance and help as you begin to assess your ERP needs and evaluate systems. Please reach out and schedule a free consultation here.

Visual South has helped hundreds of manufacturers improve their business operations, using Infor ERP at a tool to support those improvements. Click here for more information.