Jack Shannon

Recent Posts

ERP Evaluation & Comparison: A Guide For Switching Systems

By Jack Shannon on 4/3/19 10:00 AM

ERP Implementation Strategy: Advice From 30+ Years of Experience

By Jack Shannon on 3/27/19 10:00 AM

Attitude isn’t everything

I’m a fan of a “can-do” attitude. Having a positive attitude helps you overcome obstacles and get through anything life throws at you. If a new ERP implementation in a manufacturing industry is something life will be throwing at your organization, a can-do attitude is the right attitude for the implementation team to have.

Thinking About Hiring a Scheduler So You Can Use ERP Scheduling?

By Jack Shannon on 3/10/19 11:10 AM

Chances are good you don't need to hire someone

I have a certain passion for helping companies manage their capacity by scheduling properly. In this blog post, I’m going to discuss a common thought process companies go through to finally get to the point of using ERP to schedule their shop floor: They need to hire a Scheduler. Put someone in charge and have them get the company to the promised land of scheduling properly. It sounds reasonable, but in my experience, it’s a misguided strategy. Let me explain why.

ERP Scheduling Workshop

By Jack Shannon on 3/10/19 11:09 AM

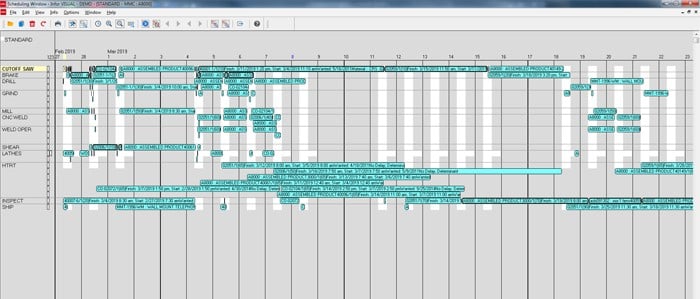

I used VISUAL ERP scheduling

When I was a Plant Manager at a rotary die manufacturer in 1994, I bought an ERP system. The biggest problem I was trying to solve was scheduling the shop floor. We were in an industry that demanded 2-4 day lead times. Everything we did was custom; each work order had around 20 operations. It was rare for me to get a question about our ability to produce a die, because we had all the right type of fabricating equipment to produce a die. The real question was if we could produce it in the lead time the customer provided. In other words, did we have enough open capacity to do what the customer wanted us to do?

Why Use ERP's Built-in Functionality?

By Jack Shannon on 12/12/18 10:00 AM

Riddle

If you had to travel from New York City to San Francisco, what’s faster, a jet or a car?

♩♫ Jeopardy music ♫♩

Right now you’re thinking, “The obvious answer is “jet”. But if that’s the right answer, this wouldn’t be a riddle.”

How to Get Great Manufacturing Analytics from Your Enterprise Resource Planning (ERP) System

By Jack Shannon on 10/10/18 10:00 AM

Why have ERP without manufacturing analytics?

If you use work orders to produce goods and aren’t getting manufacturing analytics out of your ERP system, you have an important resource that’s untapped. The good news is this can be fixed. The other good news is fixing it will lead to a smoother operating production floor with a more predictable output. There is no “easy” button, but there is a proven method you can follow to mine manufacturing analytics. Companies that use this method find managing production is easier, because they have data. They know what to fix, and just as importantly, what to leave alone. Data leads to focus, which leads to better results. It’s not magic, but it does work.

When to Use SyteLine SQL Tables for Custom Reports

By Jack Shannon on 10/3/18 10:25 AM

Oh, you’ll want a custom report

In 1789, Benjamin Franklin wrote, “In this world nothing can be said to be certain, except death and taxes.” I think he got it mostly right. He should have said: “In this world nothing can be said to be certain, except death, taxes, and the need for custom reports from your ERP system.” In Ben’s defense, computers and ERP systems weren’t invented yet, so he did the best he could...

Managing Capacity Because It's What You Sell

By Jack Shannon on 9/26/18 10:00 AM

What do you sell?

In the job shop machine industry there is a funny answer to the question, “What do you make?” The response is, “Chips. We make metal chips. The faster we make them, the better we are doing.” (Metal chips are made with a metal cutting tool removing the material you don’t want. The tools are used on equipment like a lathe or a mill. Want to know how they work? Read this.)

Summer is Over, It's Back to School Time

By Jack Shannon on 9/7/18 10:00 AM

Seek knowledge, solve issues

I hope everyone had a nice summer. Now that all the kids are back in school, maybe you should think about going “back to school” as well. Let me explain.

The Benefits of Documenting Your ERP System Procedures

By Jack Shannon on 8/10/18 10:00 AM

Floss your teeth, don't eat junk, document your procedures

My guess is the headline above didn't tell you anything you don't already know. There is a difference though between knowing and doing. You don't need me going into detail of the benefits of flossing your teeth or eating right, so I'm going to focus on the benefits of documenting your ERP system procedures. I promise you two things: This won't be a finger wag if your procedures aren't documented. Also, I will reveal an easy way to document your procedures. The third point isn't a promise, but it is a goal. I'll try to make this interesting, so keep reading.